Table of Contents

Introduction

SAP S/4HANA Manufacturing for Planning and Scheduling is redefining how organizations approach advanced production planning in an increasingly complex supply chain landscape. As customers move away from legacy SAP SCM APO PP/DS, many assume this solution is a direct successor. In reality, it is not. From a consultant’s perspective, this distinction is critical and often underestimated during early project discussions.

Unlike traditional upgrades, implementing SAP S/4HANA Manufacturing for Planning and Scheduling—delivered as part of the SAP Digital Supply Chain (DSC) Management edition—requires a fresh implementation mindset. There is no automatic migration of transactional data or custom code. Instead, consultants must design a robust side-by-side architecture, define clean integration boundaries, and align planning logic across systems.

This blog post provides a practical, experience-driven guide to help SAP consultants and solution architects understand what really matters during implementation, where the common pitfalls lie, and how to position this solution for long-term success.

Understanding SAP S/4HANA Manufacturing for Planning and Scheduling

SAP S/4HANA Manufacturing for Planning and Scheduling delivers finite-capacity planning, detailed scheduling, and advanced heuristics within a modern S/4HANA-based environment. Functionally, it covers many scenarios previously addressed by APO PP/DS, but technically and architecturally, it is a different product.

Key characteristics consultants must understand early:

- It runs in a separate DSC system in side-by-side scenarios

- Master data replication is unidirectional

- Planning objects and versions must be aligned carefully

- Not all APO PP/DS functionality exists one-to-one

Treating it as a “technical upgrade” is one of the fastest ways to derail an implementation.

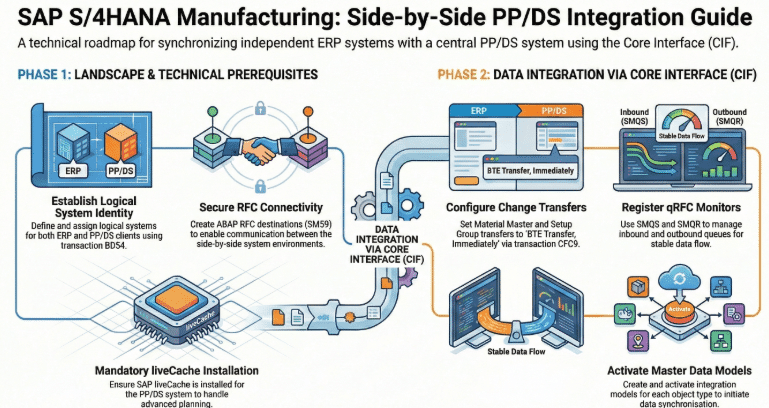

Side-by-Side Architecture: The Foundation

In most real-world projects, SAP S/4HANA Manufacturing for Planning and Scheduling is deployed side by side with one or more ERP systems. The DSC system handles:

- Production Planning

- Detailed Scheduling

- Finite capacity optimization

Meanwhile, the ERP system remains the system of record for:

- Finance and Controlling

- Sales and Distribution

- Procurement and Inventory Accounting

This architectural separation brings flexibility but also complexity. Consultants must clearly define which system plans what. Ambiguous planning responsibilities often lead to duplicated requirements, inconsistent schedules, or missing supply signals.

System Connectivity and Technical Integration

Integration between ERP and the DSC system relies on CIF (Core Interface) and RFC-based communication. This area is highly technical but foundational for system stability.

From a consultant’s perspective, success depends on:

- Correct RFC destination setup

- Proper queue registration and monitoring

- Understanding bgRFC and qRFC behaviors

Even small configuration mistakes—such as incorrect outbound bgRFC settings or missing queue registrations—can silently block master or transactional data without obvious errors.

Pro tip: Always validate connectivity using remote logon tests and actively monitor queues during initial loads.

Master Data Strategy: What CIF Does and Does Not Do

One of the most common misconceptions is that CIF will “take care of everything.” It won’t.

In SAP S/4HANA Manufacturing for Planning and Scheduling, master data flows strictly from ERP to DSC, but several objects must exist before CIF can work correctly.

Consultants must manually create or verify:

- Planning Model 000 and Version 000

- Plants and locations

- Factory calendars

- Business Partners (not CIF-enabled by default)

Only after this foundation is in place can materials, work centers, and PDS objects be transferred reliably.

Production Data Structures and Planning Control

Production Data Structures (PDS) are the backbone of planning logic. They define how materials are produced, which resources are used, and how operations are sequenced.

A critical consultant rule:

If a material is planned in SAP S/4HANA Manufacturing for Planning and Scheduling, everything above it in the BOM hierarchy must also be planned there.

Violating this rule creates unplannable components, missing dependent requirements, and planning dead ends that are difficult to debug later.

Advanced Scenarios: Characteristics and Subcontracting

Advanced manufacturing scenarios add additional layers of complexity.

Characteristics-Dependent Planning

Only specific class types are supported for integration. Consultants must ensure:

- Correct class type usage

- Organizational area assignment

- Data consistency checks during upgrades

Skipping these steps often results in incomplete or inconsistent planning variants.

Subcontracting

Subcontracting works well—but only when both systems speak the same language. MRP areas, PDS types, and integration models must be perfectly aligned. Including vendors incorrectly in CIF models is a surprisingly common mistake.

Multi-ERP Landscapes and Scalability

Large enterprises frequently connect multiple ERP systems to a single DSC system. SAP S/4HANA Manufacturing for Planning and Scheduling supports this—but only if material identities are consistent.

From a consultant standpoint:

- One material number must represent the same physical item everywhere

- Logical system separation must be clear

- Location aliases are mandatory for cross-system stock transfers

Ignoring these principles leads to data overwrites, planning confusion, and incorrect order confirmations.

Integration with SAP IBP

When combined with SAP Integrated Business Planning (IBP), SAP S/4HANA Manufacturing for Planning and Scheduling becomes part of a closed-loop planning ecosystem.

IBP handles:

- Medium- to long-term planning

- Rough-cut capacity decisions

The DSC system refines these plans into executable schedules. Changes flow back in near real time, ensuring alignment between strategic planning and shop-floor execution.

This integration is especially valuable for organisations pursuing end-to-end supply chain orchestration.

Common Consultant Pitfalls to Avoid

Experienced consultants know that most project issues are not technical—they are conceptual. Common mistakes include:

- Treating the solution as APO PP/DS replacement

- Mixing planning responsibilities across systems

- Ignoring BOM hierarchy rules

- Underestimating master data preparation

Clear governance and early design decisions prevent most of these problems.

Frequently Asked Questions (FAQs)

Is SAP S/4HANA Manufacturing for Planning and Scheduling a direct replacement for APO PP/DS?

No. It is not a legal or technical successor. It requires a new implementation approach.

Can transactional data be migrated automatically?

No standard migration exists. Historical data must be handled selectively or rebuilt.

Is side-by-side deployment mandatory?

In most complex planning scenarios, yes. Embedded-only setups are limited.

Does CIF support all master data objects?

No. Some objects, like Business Partners, require manual creation or alternative integration.

Can multiple ERP systems connect to one DSC system?

Yes, as long as material identities are consistent across systems.

Is the PP/DS Optimizer mandatory

No, but it is highly recommended for complex sequencing and capacity constraints.

- sap s4hana transition guide to data migration

- sap clean core

- SAP S/4HANA private cloud 2025

- introduction sap btp for consultants

- sap consultants productivity with joule

- Migration guide to SAP data migration

- SAP btp guide to app development

- Transformation journey 4hana implementation

- Empowering enterprises with SAP solutions

- blackline tool vs traditional process

- Sap cutover plan a comprehensive guide

- Fiori Configuration Guide

- SAP ECC to S4HANA data migration

- earn sap btp

- Retail insights with sap car

- leanix an introductory guide

- building side-by-side extensions on SAP BTP

- sap ecc vs s4 hana key changes and benefits

- sap ides

- Understanding RFNO in SAP s4hana

- SAP Clean Core

- SAP ABAP beginner’s journey

- Grow with sap vs rise with sap comparison

- Rise with sap

- Year-end activities in sap

- SAP TM Transaction codes

- ethical ai development

- sap migration data configuration tools

- Simplifying SAP s4hana custom code migration

- SAP EWM integration

- sap project intelligence network

- advanced production integration with SAP EWM

- Credit management comparison of sap fscm

- SAP EWM

- sap s4hana migration

- GST E invoice

- understanding abap objects

- SAP interfaces

- Joule ai copilot

- Mastering sap background job processing

- SAP Ewm tcodes a handy guide

- Object-oriented programming in sap abap

- understanding sap license costs

- SAP Datasphere

- industry4.0 with sap

- Condition contract management in sap s4 hana

- Comprehensive guide to go live

- SAP EHS Module

- Power of generative ai in sap

- SAP Joule Comprehensive Guide

- Mastering the dunning process sap

- Creation of chart of accounts in sap fico

- Different roles of an sap consultant

- understanding sap system landscape

- Product costing in sap

- Copa in sap

- subcontracting process in sap mm

- SAP S4hana cloud

- Disaster Recovery in SAP HANA Cloud